×

The LASER TAGMARK is a FULLY AUTOMATED LASER MARKING STATION that will allow you to simultaneously manage the marking of your plates, on a SINGLE, SAFE AND SYNCHRONISED WORK STATION with your own data.

PLATES ARE MARKED IN SERIES, AUTOMATICALLY. Operator presence is not necessary.

The TAGMARK LASER can be equipped with lasers of VARIOUS POWER RATINGS, for deeper marking or marking at higher rates.

The ytterbium-enhanced SIC Marking fibre laser is a latest generation technology that enables high quality marking without affecting the piece, and with a shorter cycle time.

After marking, the plates are removed into a recovery tray or, on option, by a plate gravity stacking system.

Marking is also possible on individual parts if desired.

Direct loading into the marking zone also allows plates of formats other than those programmed in the loading zone to be marked.

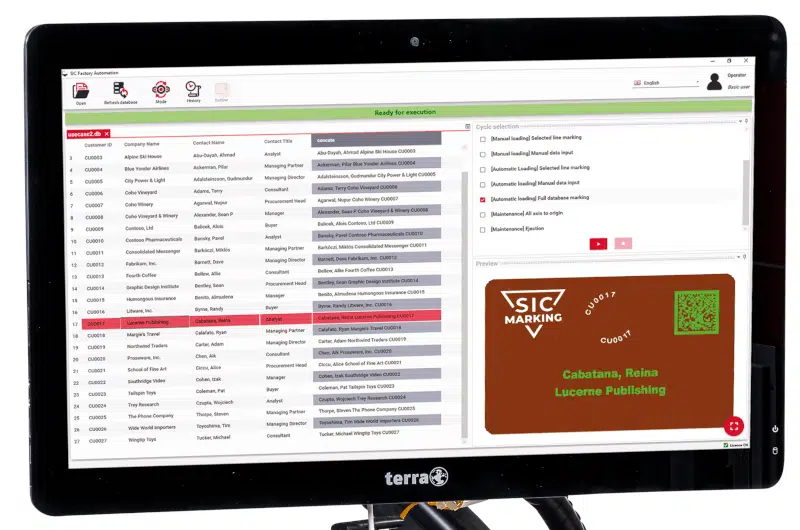

The new SFA (SIC FACTORY AUTOMATION) control software is compatible with your data management system. Data entry will thus be automatic and you will have an optimised, configurable and user-friendly HMI.

The SIC FACTORY AUTOMATION software interface is designed to simplify the setting up and utilisation of the TAGMARK LASER.

The SFA software manages your marking needs, in your own selected language based on your user profile: operator, advanced user, supervisor.

It can be used in Manual mode or in Database mode, compatible with your production management systems.

It can also be customised beyond predefined cycles and conserves your data history.

100 x 100 mm – 170 x 170 mm

200 mm – 330 mm

Laser class 1 or 4, depending on integration

With SFA and PC

SIC Marking ytterbium-enhanced fibre laser

Pulsed (variable frequency)

1064 nm

3 m

20W, available in 30W

7 kW

Integral laser pointer

Air cooled only

Yes

SFA (SIC FACTORY AUTOMATION)

For cycle management

INTEGRATED READ FUNCTION

FUME EVACUATION SYSTEM

COWLED CHASSIS

Contact us

Need information?

Contact one of our experts!