×

nos solutions > gamme atelier > stations laser

FIT LASER is an all-in-one integrated marking solution, containing all the protection you need for efficient, safe marking of your parts on the production line.

The FIT LASER marking system is designed for Class 1 integration, guaranteeing the protection of nearby personnel thanks to a beam enclosed in a radiation-tight sheath.

An integrated mechanical compensation system enables simple installation in your production.

It compensates for robot arm position deviations and part tolerance variations by up to 15mm.

It guarantees optimum laser focal distance and perfect marking quality.

Contact one of our experts !

Phone: +1 450.449.9133

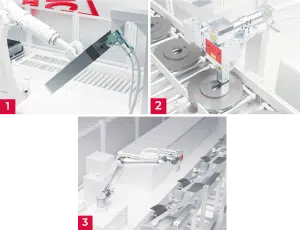

1. In fixed position: The part is fed to the FIT

2. On linear axis

3. On Robot or Cobot , FIT goes to the piece *contact SIC MARKING

30 x 30mm – 50 x 50mm – 60 x 30mm – 100 x 30mm

Custom-made

20W – 30W – 50W – 60W

13kg

Ready for Class 1 integration

PL-e

Profinet – Ethernet IP – OPC UA – Profibus

Contact an expert for more information

Whatever your questions or projects, we are here to listen to you!