×

You need to reconcile performance, safety and regulatory compliance when managing your machinery and vehicles. Whether you’re a manufacturer, operator or rental company, SIC MARKING designs reliable industrial marking solutions tailored to the specific needs of your sector (construction, agriculture, rail, heavy vehicles, maritime, soft mobility, etc.).

Your challenges

Key standards

Our solutions

Your challenges

Key standards

Our solutions

Your challenges

Key standards

Our solutions

Your challenges

Key standards

Our solutions

Your challenges

Key standards

Our solutions

Your challenges

Key standards

Our solutions

With SIC MARKING, you can count on traceability that is reliable, compliant and easy to implement.

Contact our experts to help you manage your machinery and vehicles more efficiently and safely!

They trust us

Our test laboratory allows us to test the best laser or dot peen marking solutions on parts that are often in aluminium alloy, titanium or stainless steel, before each project.

In the transport sector, where marking reliability and traceability are essential, SIC MARKING puts its test laboratory at your disposal to define the tailor-made solution that precisely meets your needs. Our LASER, MICRO PERCUSSION and RADIATION technologies ensure legible engravings in all conditions (even under thick coats of paint), guaranteeing reliable, long-lasting traceability for your equipment markings.

Our practical applications

Rail transport

A pioneering rail rolling stock company, that develops, manufactures and supplies wheels, wants to ensure train wheel traceability.

This traceability needs to be evident right along the production line, as well as retracing lifecycle tracking in the event of a quality issue.

The wheels are machined on different workstations and conveyed by an automatic system.

All the models are different and are not consecutive.

The marking system must therefore be able to respond rapidly to these variations, with no human action being required.

Cycles and motorcycles

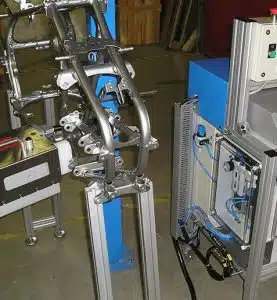

A seemingly conventional request, as it involves marking a VIN chassis numberon the frames of motorcycles, scooters and quads.

The aim is to develop a specific tool to ensure that the marking gun is held against the frame to be marked.

An appropriate tool has to be designed for each marking zone.

These tools must be attached directly to the marking gun mounted on a balancer.

The balancer is held against the frames by a pneumatic clamp.

Heavy vehicles

A German group, a leader in the automotive sector, uses SIC MARKING expertise for marking VIN chassis numbers on its cars, vans and trucks.

The number marked is internationally acknowledged by all authorities and government departments responsible for approving and regulating vehicles.

Agriculture

The customer wants to create a standard identifier plate for their various production sites around the world: France (5 plants), USA (2 plants), Germany, Italy, China, Brazil (2 plants) and the Netherlands.

Our product lines

Discover other sectors

Throughout our 30 years of development, we have built up our expertise in the automotive, energy, mechanical engineering, vehicle and transport industries.

Discover below our

many examples of laser, dot peen or scribe marking applications in each of these sectors.

Contact us

Need information?

Contact one of our experts!