×

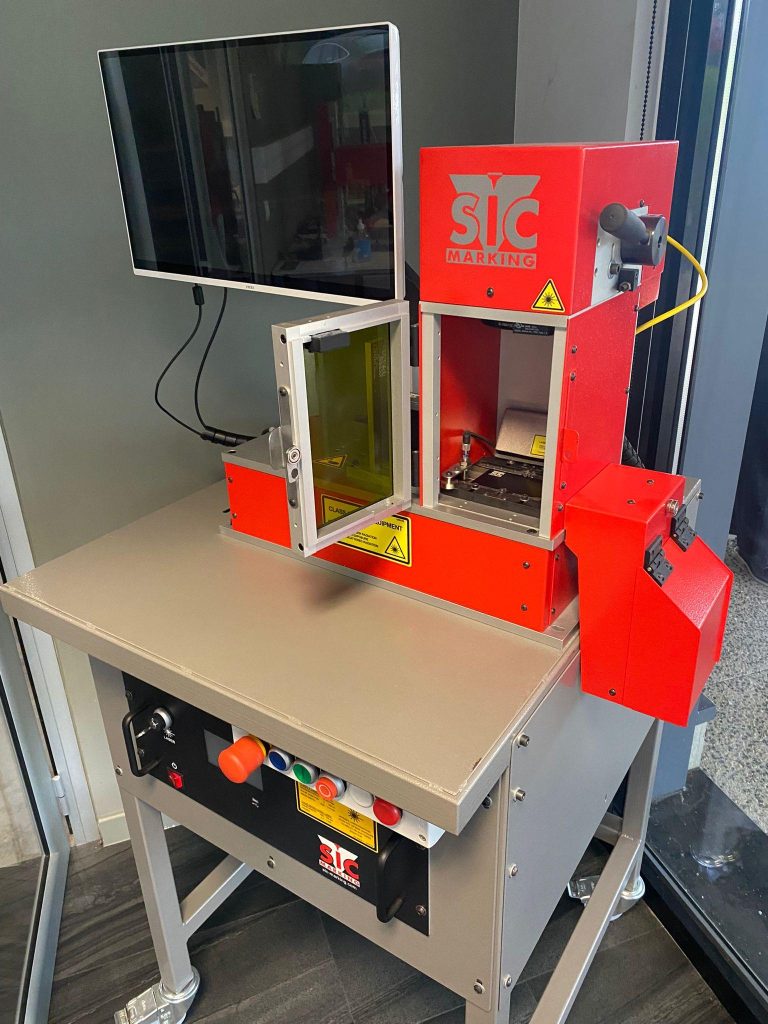

Today we would like to introduce one of our star products: the TAGMARK Laser Station. It is a complete and automated station specialized in automatic plate marking, which allows simultaneous supply and marking of plates. In addition, it is a single workstation, secure and synchronized with your database.

If you are hesitating about whether or not it is the laser station you need, with this article we want to convince you of all the benefits you can get using the TAGMARK Laser from SIC Marking.

Before going into more detail, some of the points to highlight are:

Laser marking is recommended for medium/high production, where precision and speed are necessary conditions. Used especially for Direct Part Marking (DPM) or Plate Marking, the final result is clear, precise and legible to the naked eye, or verifiable through code readers. It is undoubtedly a very interesting option within the laser marking sector, thanks to its numerous features, which allow to offer precise and quality results.

Video extracted from SIC MARKING ITALIA channel

Although it may be a bit tedious, it is important to know in detail the different features offered by the TAGMARK Laser Station. Below, we explain them in order to show you and convince you that this laser station is one of the best options available on the market.

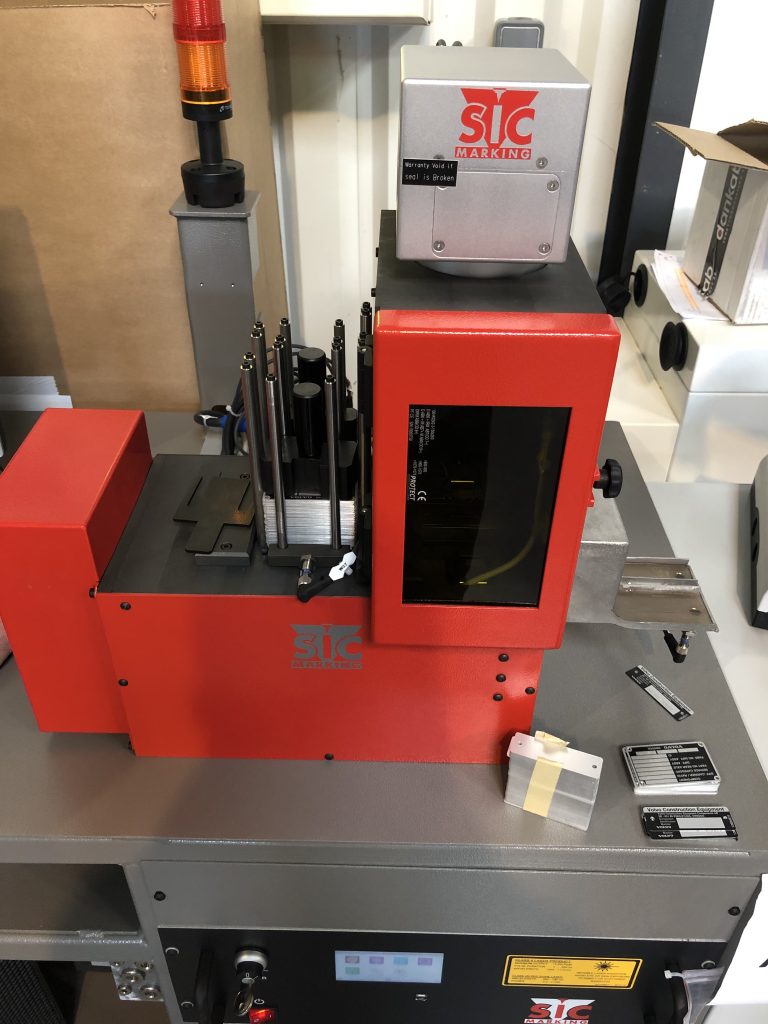

Optimized plate processing

The machine is equipped with one marking path for plates of the same size, or with two paths for two different sizes. Standard storage height is 150 mm.

The TAGMARK Laser is equipped with a plate container. A drop-down plate collection system is available as an option.

Powerful laser source and control unit

The TAGMARK laser marker is available in standard or dedicated mode, as a stand-alone station or integrated in the production line. The standard mode is provided with an i104 EASY laser machine with 20w fiber source (higher powers or speeds are available for deeper engravings).

Technology

Source: pulsed fiber laser (variable frequency).

Power: 750W.

Wavelength: 1064NM.

Digital axis control: linear and rotary.

Administration

Configuration: Through SIC FACTORY AUTOMATION software.

Communication: USB interface, Windows environment.

UX: intuitive interface with navigation and icons.

SIC FACTORY AUTOMATION: An intuitive software.

The SFA software offers user profiles, predefined cycles and the ability to customize your own marking cycle.

Data import

– File selection and data entry with 1D or 2D barcode reader.

– Import of marking data: references, variables, number of plates.

– Database formats: csv, xlsx or xls.

Marking preview

– Instantaneous display of the part marking on the screen.

3 user profiles

– Operator: standard launch of a predefined marking cycle.

– Advanced User: possibility to modify the marking criteria of a predefined cycle.

– Supervisor: customization and editing of advanced configurations.

Plate feeder

The machine is equipped with one plate magazine for references of the same size, or two types of magazine for references of two different sizes. The standard stacking height is 150 mm.

Marked plate container

TAGMARK LASER is equipped with a plate container. The container collects the plates in an orderly manner by gravity and is available as an option.

Plate specifications

* The combined width of the two plates should not exceed 170 mm. Plate thickness: 0.5 to 2 mm.

Tag dim. (mm) MinimumwidthMaximumwidthMinimumlengthMaximum length1charger12100301002chargers12170*30130

We are aware that making an investment of this caliber, requires having the necessary conviction to do it, for this reason, if you want to consult or have any questions about the TAGMARK Laser Station or other solutions for industrial marking of your products, contact us without obligation. At Sivart/SIC Marking we are happy to offer you the solutions that best suit your project.