×

case study

A German group, a leader in the automotive sector, makes use of SIC MARKING’s expertise for marking VIN chassis numbers on its light and heavy vehicles.

The number marked is internationally recognised by all the bodies and government departments responsible for approving and regulating vehicles.

For years, the automotive group has relied on SIC MARKING’s solutions for its flawless marking processes, which are capable of adapting to its production constraints.

The group’s requirements in terms of traceability are very stringent and, as required by the standard, markings must be robust , remain legible for the vehicle’s entire life and withstand

attempts to falsify them.

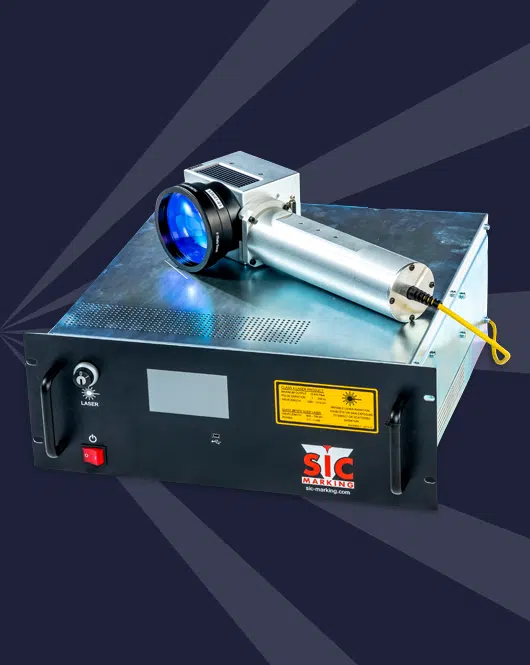

In order to fulfil this specification, SIC MARKING developed an i104 L-G 100W laser engraving solution.

● This custom station was delivered ready-to-use (turnkey), for prompt start-up in line with the manufacturer’s summer programme of work.

● This engraving laser is mounted on a carriage structure with free 3D manual positioning.

● The exact position of the laser head for marking is obtained thanks to a fully spring-loaded zero force manual robot arm.

● Precise guiding of the laser head is ensured by a tool guaranteeing the flawless repeatability of marking.

Contact us!