×

At Sivart/SIC Marking we are aware of the large number of variants to which we can offer a solution through our integrators.

We are specialists in both marking and traceability solutions. Our marking machines are recognized for their robustness, reliability and quality. Thanks to the design of our integrators you will increase productivity and offer unmatched marking quality and traceability of all types of components.

Traceability by direct part marking or DPM (Direct Part Marking) is a process used in a large number of industrial sectors for product identification. Direct marking is more reliable than other options, such as the application of labels.

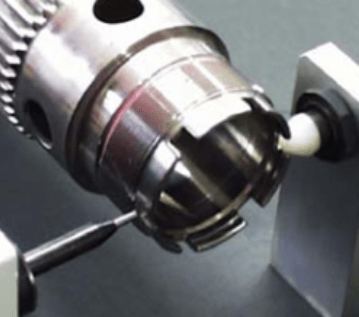

Marking systems using technologies such as laser, micro-percussion, or scribing engrave high quality and clear codes in a wide range of production conditions. Permanent marking directly on the part enables better traceability and facilitates production automation, lot control, inventory management, quality control/storage defect and eliminates rework errors.

The integration of an automatic system in a production line generates constraints:

Our commitments:

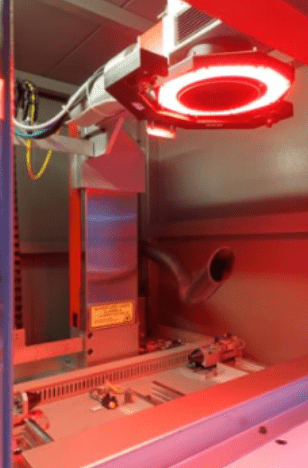

Our integrable marking machines are appropriately designed to be placed in the center of production lines and used intensively. Their easy integration as well as their high performance make them indispensable products for manufacturers. In addition, there is the possibility to adapt them to your specific needs and include camera playback systems.

At Sivart/SIC Marking we provide a complete marking reading service and also enable communication between systems through specific software for analysis, report editing and backup of the different data. The excellence in the traceability of all types of parts is closely related to the quality of the marking of characters or data matrix codes, to the vision reading system and to the communication.

Example:

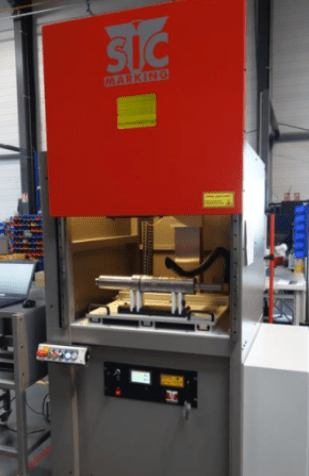

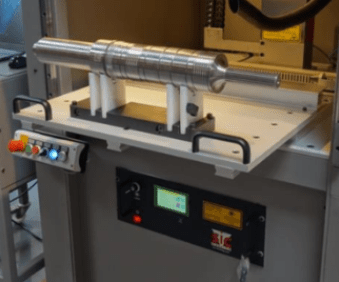

Specific application – Elevator motor shafts

Customized 20 W laser station on the basis of an XXL Box 800 mm with automated X and Z axes + integrated vision for 2D code verification.

16 axes in various lengths, 9 alphanumeric + 11-digit DMC in less than 24 seconds.

If after reading this article you are interested in some of our solutions specially designed for our integrators, contact us without obligation. We will be happy to help and advise you on the best solution for your company or needs.