×

In the construction and off-road vehicle industry, Direct Part Marking (DPM) is essential to ensure long-lasting identification on metal components operating in harsh environments.

Off-road equipment is constantly exposed to mechanical impacts, abrasion, and corrosive conditions. These extreme environments can significantly degrade the surface of critical parts, making identification and traceability difficult over time.

To address these challenges, SIC MARKING designs industrial engraving machines specifically adapted to mark metal parts under heavy stress. These solutions guarantee durable, readable, and compliant markings that meet the industry’s strict traceability and safety requirements.

Depending on the required marking depth, readability, and resistance, SIC MARKING offers a range of robust marking technologies:

In the off-road construction equipment sector, compliance with marking and traceability standards is critical to ensure safety, regulatory approval, and effective tracking of equipment and components.

Manufacturers and end users of off-road machinery must adhere to specific standards established by international and national regulatory bodies.

These requirements cover equipment identification, spare parts traceability, and risk prevention related to the use of machinery in harsh operating environments.

Direct part marking (DPM) is the ideal solution to meet these challenges, offering long-term durability, readability, and the ability to customize markings for each component.

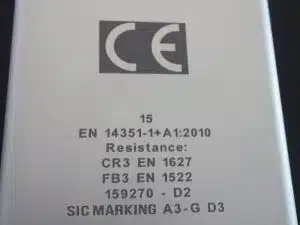

CE certification (Europe): for product conformity and safety

ISO standards: for quality management, traceability, and operational safety

SAE standards: specific to construction and heavy-duty equipment

NF standards (France): for national compliance in marking and part identification

SIC MARKING develops and supplies industrial marking systems specifically designed to meet the demands of direct part marking on mechanical and structural components of off-road construction machinery.

Off-road vehicles and equipment are specially designed to operate on rough, unpaved, and hard-to-access terrain.

They are widely used across industries such as construction, forestry, mining, agriculture, and extreme terrain transport.

Direct part marking is essential to ensure the durability, traceability, and regulatory compliance of critical components used in these demanding environments.

Industry > Off-road construction equipment

Earthmoving machines—such as excavators, bulldozers, graders, wheel loaders, and articulated dump trucks—operate in extreme environments where durability and traceability are essential.

Permanent marking ensures clear component identification, facilitates equipment management, and supports compliance with strict safety standards.

Examples of DPM applications:

Material handling equipment is key across sectors such as construction, logistics, and manufacturing.

Direct part marking enhances traceability, ensures regulatory compliance, and improves operational safety.

These machines must meet strict standards like CE, EN 280, and EN 1459.

Examples of DPM applications:

In lifting applications, direct marking of critical parts is crucial for both safety and compliance.

Whether for forklifts, aerial work platforms, telehandlers, pallet trucks, or gantry cranes, these machines contain parts exposed to heavy loads, vibration, and harsh weather.

Examples of DPM applications:

Forestry equipment—including skidders, harvesters, forwarders, mulchers, and forestry tractors—operates in muddy, wet, abrasive, and high-vibration environments with temperature variations.

Direct marking is key to ensuring traceability, facilitating maintenance, and ensuring operator safety.

Examples of DPM applications:

Off-road mining equipment—such as haul trucks, track loaders, dozers, drilling rigs, and hydraulic excavators—is used in extreme environments: abrasive conditions, high temperatures, vibrations, dust, and chemical exposure.

Durable marking is critical for traceability, maintenance, and regulatory compliance.

Examples of DPM applications:

Contact-us

Need help ?