×

case study

A pioneering rail company involved in the development, production and supply of wheels, was seeking to ensure the traceability of train wheels. This traceability needs to be evident right along the production line, as well as retracing lifecycle tracking in the event of a quality issue.

The wheels are machined on different workstations and conveyed by an automatic system.

All the models are different

and are not consecutive.

As a result, the marking system must be able to respond rapidly to this variation, without human intervention.

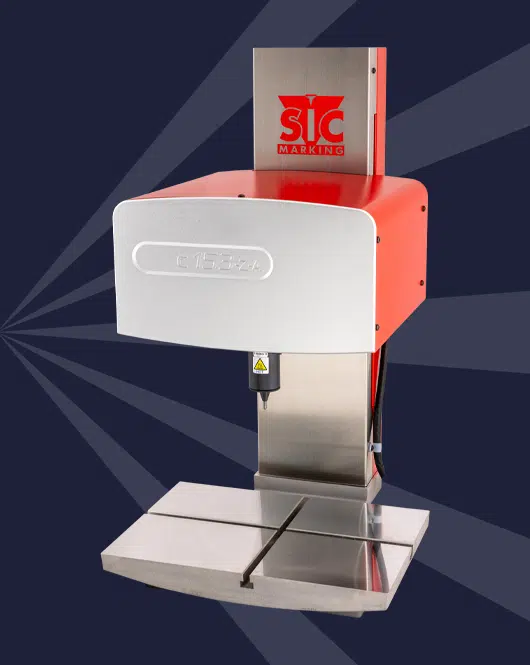

This wide variety of wheel models and sizes requires a customised professional dot peen marking solution.

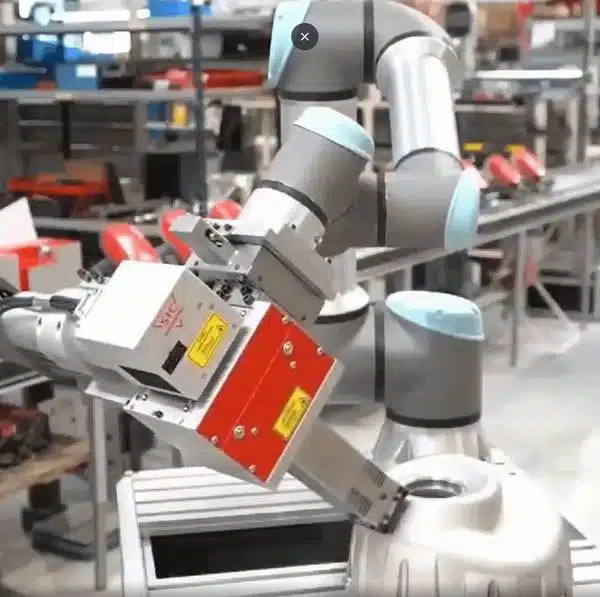

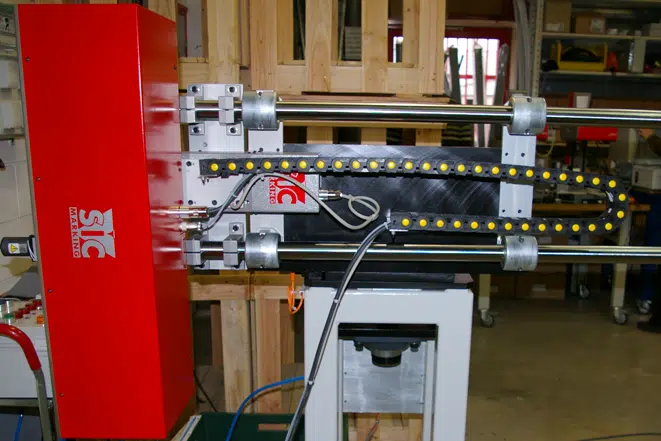

SIC MARKING developed a specific machine with a head benefiting from a large marking window and an i143 nozzle.

This head enables all the marking areas to be covered.

This vertical dot peen marking machine is equipped with:

This solution perfectly satisfies the client’s requirements, as it rests directly on all the wheel models thanks to the use of a Z axis.

Contact us!