case study

Marking on variable size chassis in hard-to-access areas

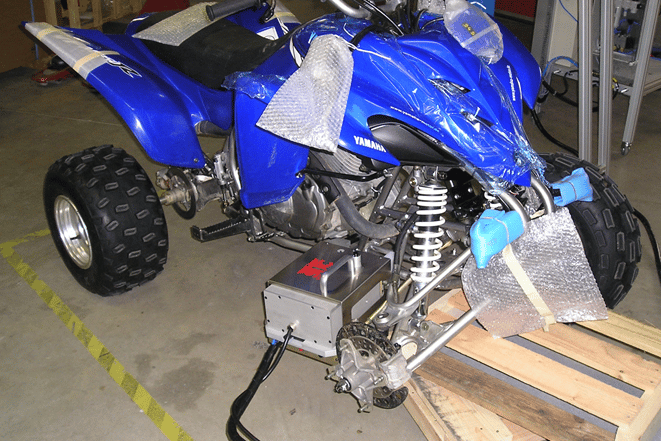

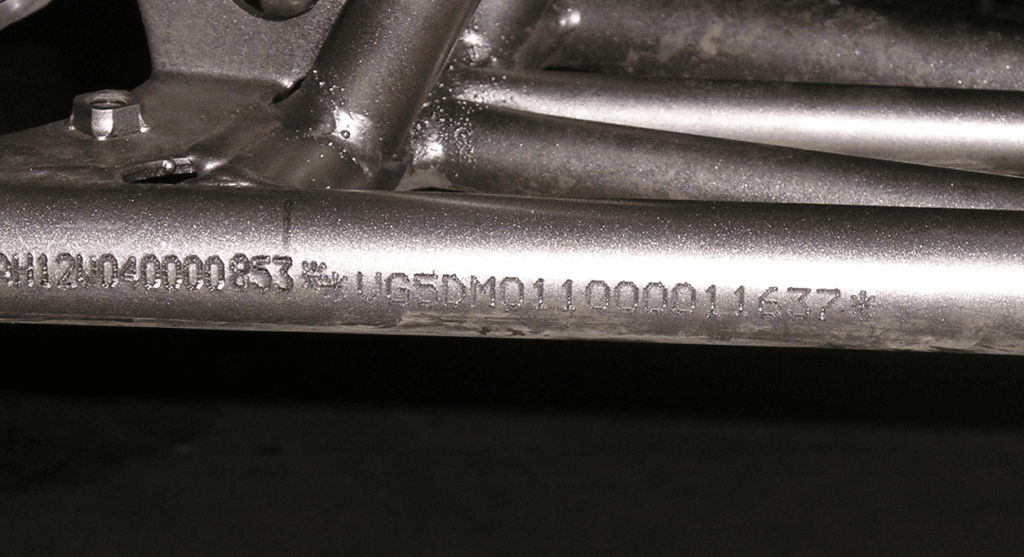

A seemingly conventional request, as it involves marking a VIN chassis number on the frames of motorbikes, scooters and quad bikes.

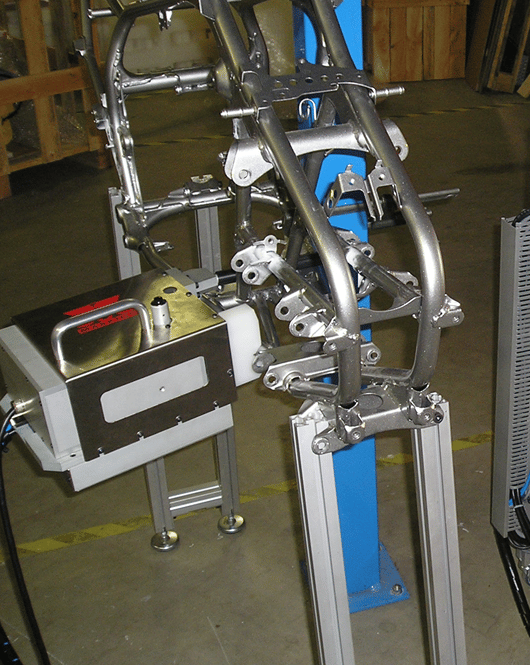

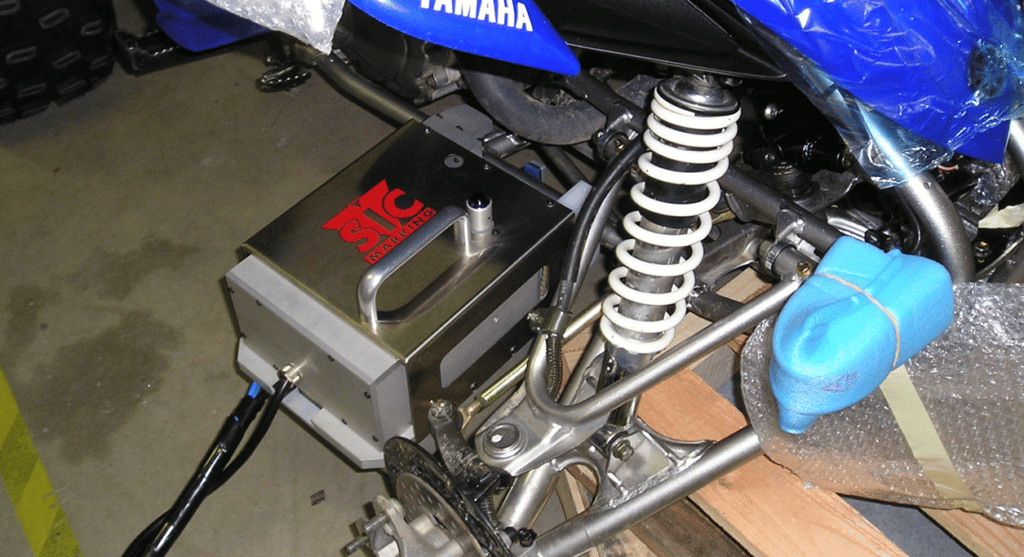

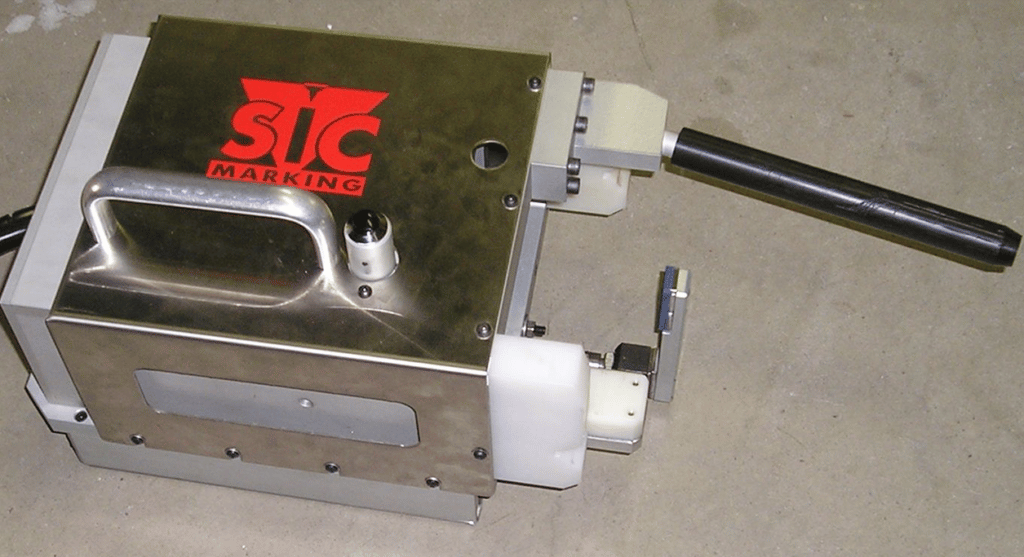

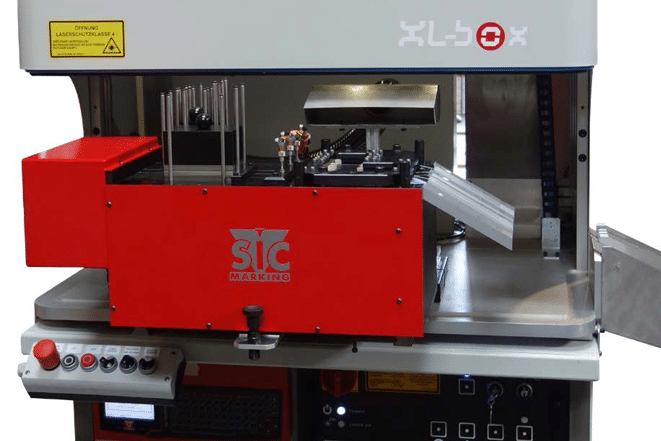

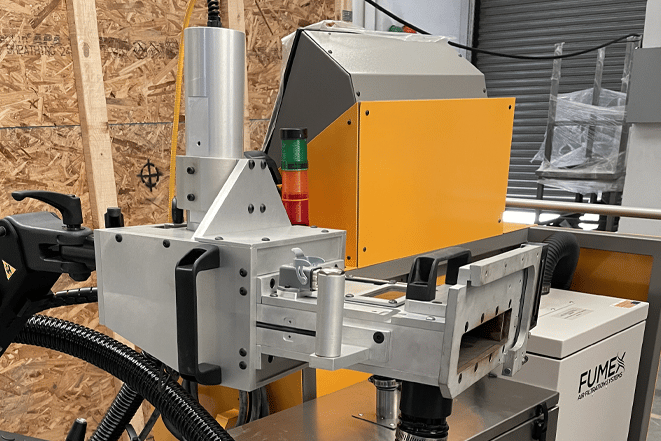

The aim is to develop a specific tool to ensure that the marking gun is held against the frame to be marked.

It is essential to design

a suitable tool for each marking area.

These tools must be attached directly to the marking gun mounted on a balancer.

The latter will be held against the frames by a pneumatic clamping cylinder.