×

case study

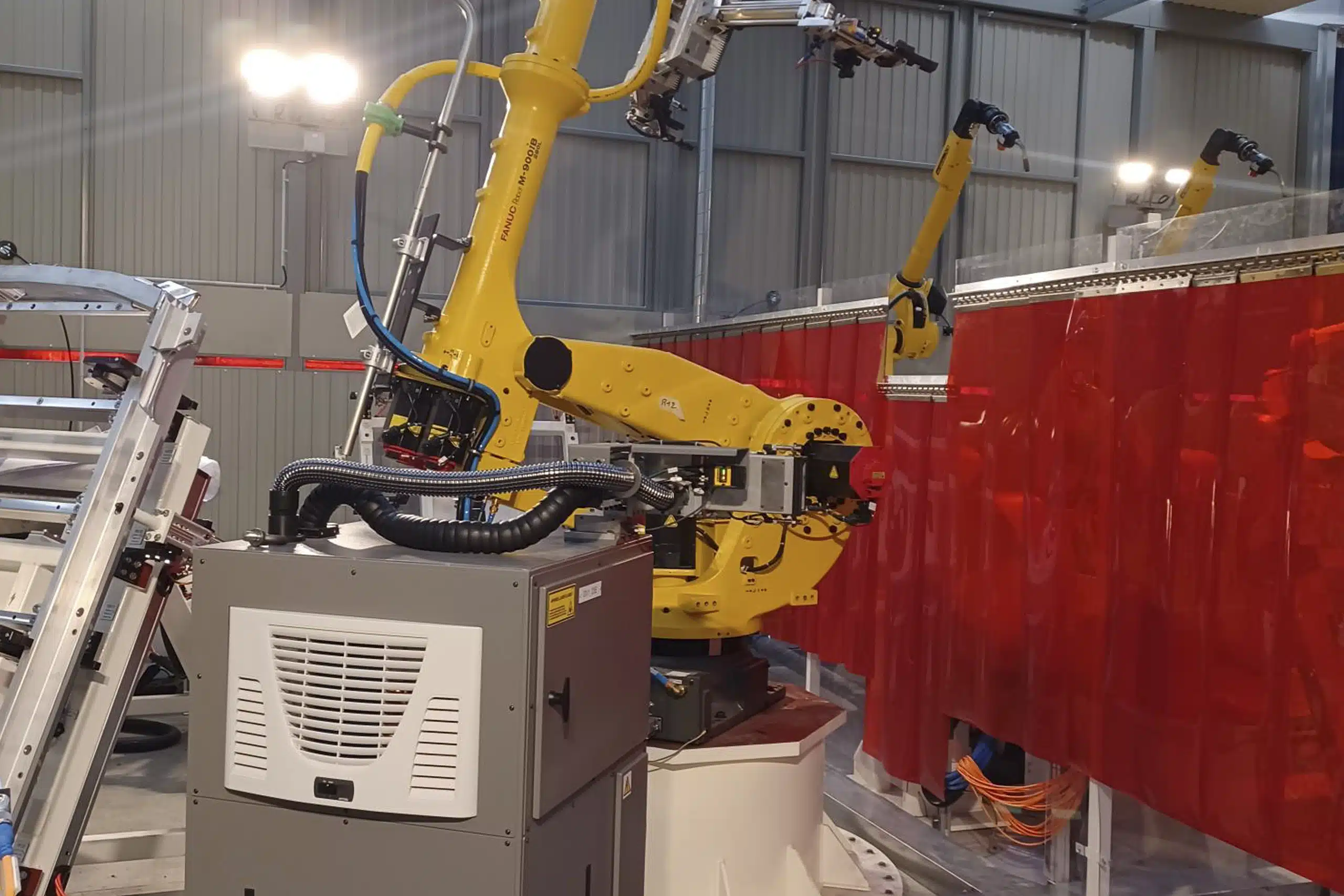

For this order, the multinational automotive manufacturer, which has a site in France, approached us via its integrator.

It involves marking battery cases in a specific environment.

The automotive group wanted to mark a Data Matrix and alphanumeric code in a robotic station, as the part is handled by a robot.

The challenge is to mark and read a 2D code in an industrial environment where SIC MARKING absolutely must take account of two significant constraints.

The solution developed by SIC MARKING resolves both issues.

In effect,

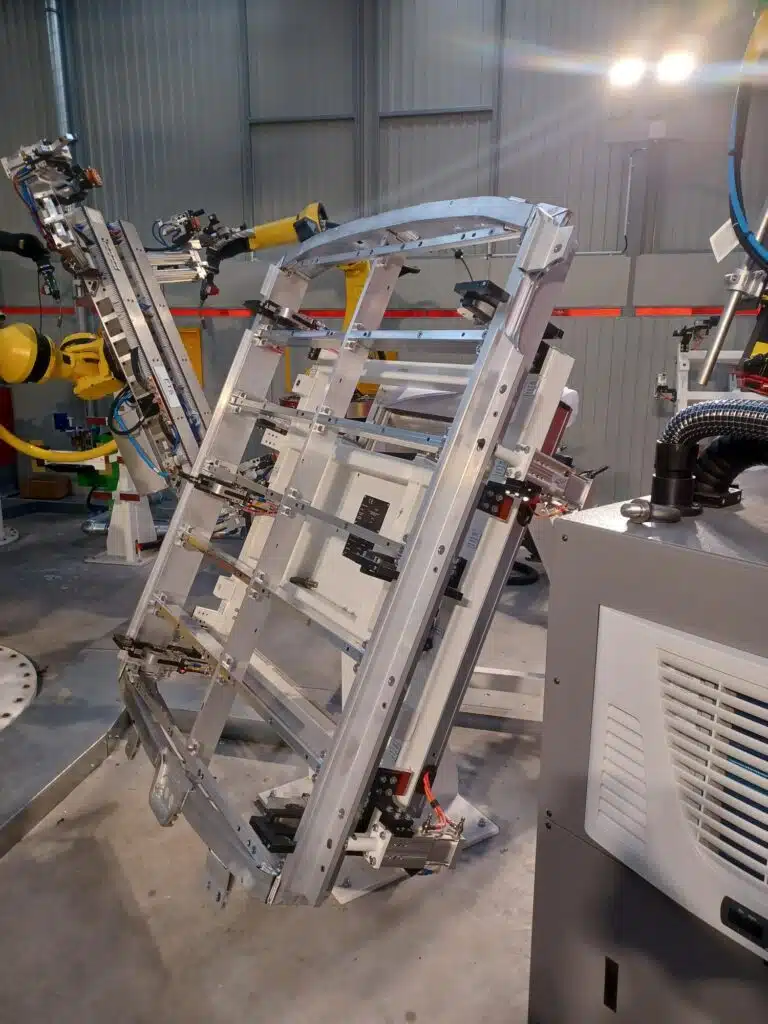

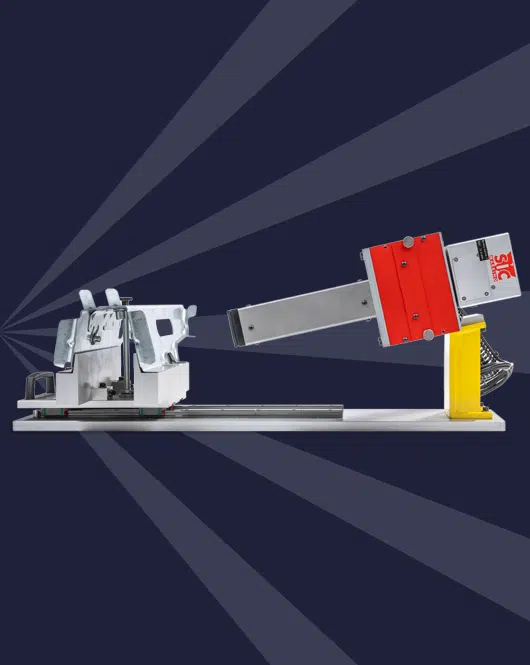

the robot presents the part directly in the standard F.I.T. LASER integrable station.

There is no need for a closed compartment or chamber, as the integrable solution designed by SIC MARKING covers safety in relation to marking.

Movements involving placing the part in the compartment and removing it are no longer necessary, guaranteeing a significant time saving.

Integration of the F.I.T. LASER is quick and easy.

It enables the

cycle time to be reduced and takes up very little space in the workshop.

This proposal offers the client an additional benefit, as this principle is more economical than a machine with a large chamber.

Specification: As an option, SIC MARKING proposed a complete sub-assembly compatible with the client’s other issues, such as high temperatures (up to 45 degrees). It is possible to add air conditioning to the frame.

This

complete frame (control unit, suction unit, etc.) with the funnel positioned on the top is directly integrated into the station.

In addition, the F.I.T. LASER’s mechanical compensation allows it to be independent of dimensional variations in the part (aluminium casting) and to adapt to the position of the part in the robot gripper.

Contact us!