×

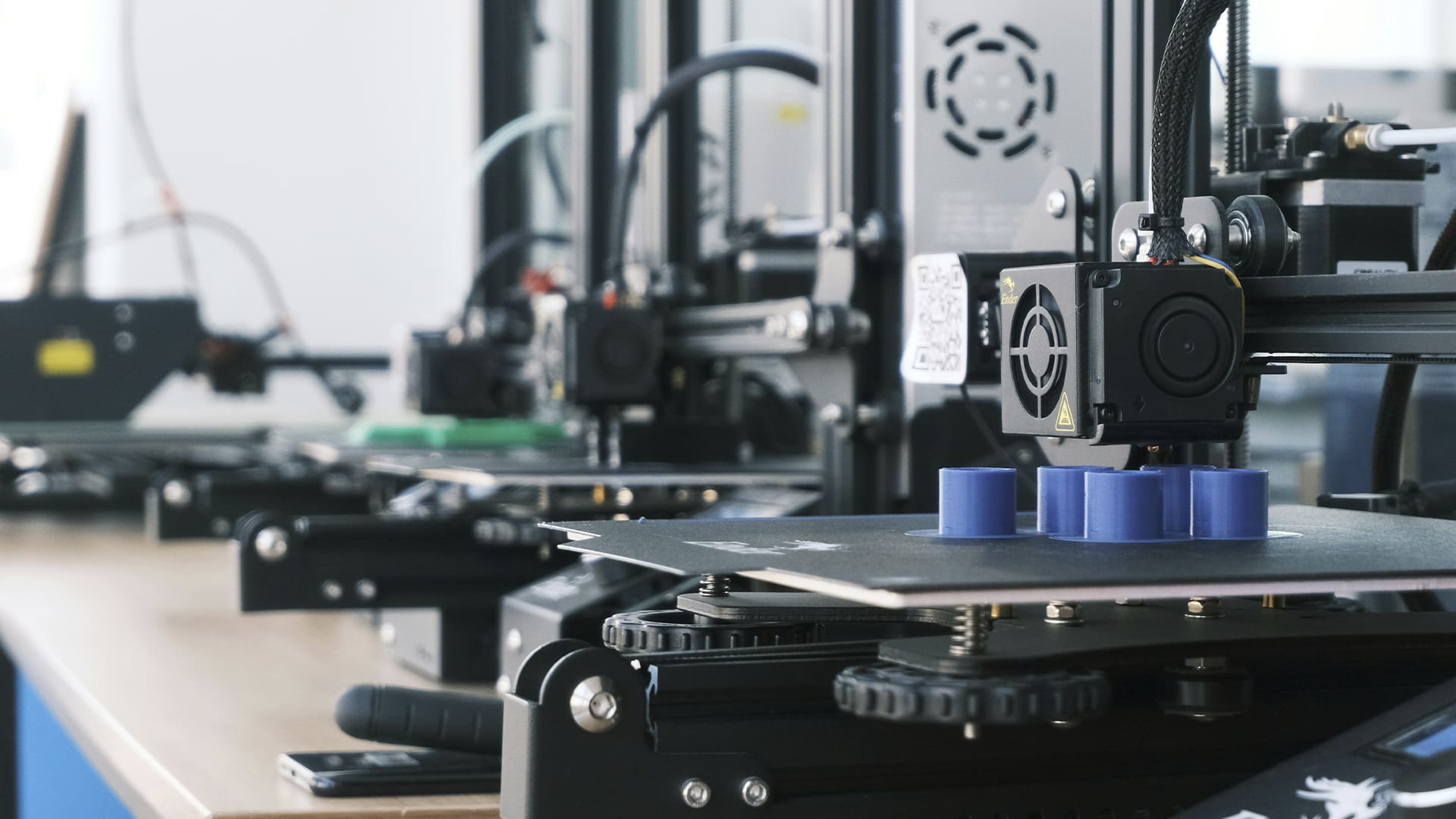

Additive manufacturing or 3D printing has transformed the way parts are designed and produced in sectors such as automotive, aeronautics and medicine. Thanks to this technology, it is possible to create customized components, reduce material waste and speed up manufacturing processes.

However, the unique nature of each 3D printed part poses a challenge: how to ensure its traceability and authenticity? This is where laser marking plays an essential role.

At SIC MarkingIn addition, we offer laser marking systems designed to integrate with the most innovative technologies, including 3D printing. Our solutions enable companies to marking, reading and tracing your parts with maximum precision, ensuring identification and safety in any production environment.

Thanks to our experience in industrial traceabilitywe help manufacturers comply with identification and quality control regulations, ensuring that each 3D printed component has a complete and verifiable history.

The future of industrial production is linked to customization and efficiency. The combination of 3D printing and laser marking not only improves product traceability and safety, but also contributes to sustainability. sustainabilityby reducing material waste and eliminating consumables such as inks and labels.

With advanced technologies such as SIC Marking, additive manufacturing can reach new standards of quality and precision. new standards of quality and precisionensuring that every part, no matter how unique, has the identification it needs.